|

Instrument Database:

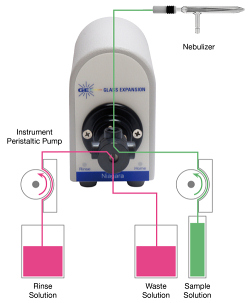

Glass Expansion - Niagara CM - Rapid Rinse Accessory

| |

|

|

| |

|

| |

|

| Year of introduction |

2013 |

| Status |

historical ( out of sale ) |

| Company |

Glass Expansion

|

| Categories |

Sample introduction: Rapid Rinse Accessory

|

|

Most ICP systems incorporate an autosampler. With these systems there is a significant delay between the time when the autosampler probe enters the sample and the time when the sample reaches the nebulizer. There is a similar delay between the time when the probe enters the rinse solution and the time when the rinse solution reaches the nebulizer. If these delays could be eliminated, the analysis time per sample could be reduced significantly and the sample throughput increased.

This is what the Glass Expansion Niagara CM Rapid Rinse Accessory achieves.

The Niagara CM begins the rinsing of the nebulizer and spray chamber the instant the sample measurement is completed and continues to rinse until the next sample is ready. Thus the rinse is carried out in the time that is usually wasted waiting for the sample and the rinse solutions to flow from the autosampler to the nebulizer.

The Niagara CM incorporates an electronically controlled switching valve and the parts of the valve in contact with the sample are made entirely of Teflon and PEEK for maximum chemical resistance. During the sample measurement time, the rinse solution is pumped through the valve to waste (see Fig above). At the completion of the sample measurement, the valve switches instantly and the rinse solution is directed to the nebulizer. The valve stays in this position while the autosampler probe moves to the rinse position and then on to the next sample. Only when the next sample has made its way through the full length of the uptake tubing does the valve switch back to the position shown in the Fig. abobe. The time that is saved is around 30% for a typical analysis.

|

|