|

Instrument Database:

Foss A/S - Process Analytics Diary

| |

|

|

| |

|

| |

|

| Year of introduction |

|

| Status |

available |

| Company |

Foss A/S

|

| Categories |

Spectrometer ( Molec. ): NIR

|

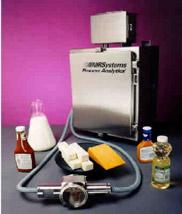

The Process Analytics™ concept for in-line measurement and process control of dairy products allows for direct installation in dairy environments. The analyser concept combines a high-energy, full-scanning NIR monochromator with high-quality fibre optics and sample probes.

The probes are installed in the process flow line for either transmission or reflectance. They are made of food grade materials and they resist high temperature, high pressure and CIP liquids.

Benefits and features

Process Analytics™ is the state-of-the-art solution for installation and in-line process control in dairy processes. It is equipped with the technology of the 90s and the chemometric software supports excellent calibration performance. Process Analytics is designed, so it can be installed under harsh environmental conditions, close to the measuring point.

The rugged Process Analytics solution has a high uptime. The transmission and reflectance probes have sapphire windows. Fiber optic bundles ensures even higher performance accuracy for more saving opportunities.

More than 6000 Process Analytics units are sold worldwide and the FOSS organisation and our NIRS specialists are ready to provide the necessary after sales support.

The reasons to apply non-destructive, inline, process control with Process Analytics in low moisture dairy products are tighter quality control and higher yielding.

Tight process control means more frequent results, stable production and uniform quality. New component targets are adjusted according to expected analytic performance and optimised product composition. Improved profit is based on saved components, cheaper analyses and saved labour.

Together with our process control software package ProcessTouch™ some processes can be automatically controlled and the number of measurements can be increased to several data points per minute.

|

| Specifications |

|

Technical specifications

Process Analytics™ model 5000 and 5500 is a factory-configured package. The system configuration is based on actual field experiences and usage and on the requirements set by food and dairy manufactures.

General spectrophotometer specifications:

Scan time

1.8 scan/second

Wavelength range (model 5000)

1100 - 2500 nm

Wavelength range (model 5500)

700 - 1100 nm

Wavelength accuracy

- Polystyrene std. to instrument +/- 0.3 nm

- Instrument to instrument +/- 0.1 nm

Instrument precision (standard deviation of 10 consecutive scans)

+/- 0.01nm

Spectral bandwidth (400 - 2500 nm) (peak width at half height)

10 nm +/- 1 nm

Working range (model 5000: 1100 - 2500 nm)

2.0 AU

Working range (model 5500: 700 - 1100 nm)

5.0 AU

Linearity (2% to 99% reflectivity or transmissivity)

+/- 1.0%

Stray light

< 0.1% at 2300 nm

Operative temperature

15°C - 33°C (59 °F - 92°F)

Power consumption

150 watt (maximum)

|

|