|

Instrument Database:

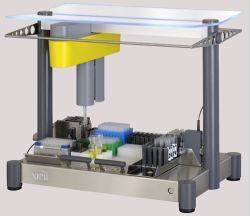

Xiril AG - Xiril X75 - Liquid Handling Platform

| |

|

|

| |

|

| |

|

| Year of introduction |

|

| Status |

historical ( out of sale ) |

| Company |

Xiril AG

|

| Categories |

Automation: Workstation

|

An ideal liquid handling platform for the entry-level market with an outstanding functionality / price ratio.

Pipetting, plate handling, barcode reading, and shaking etc. are built onto a small footprint to make the X75 ideal for reformatting, archiving, compound dissolution, hit picking, and normalisation.

Highlights

Xiril robotic systems combine liquid handling and robotic manipulation to create a space-saving flexible instrumentation concept designed for the low-end pipetting market. The open platform can be adapted to a wide range of life science applications with optional arm and tip configurations and simple integration of modular hardware components. Three instrument footprints are available (Xiril 75, 100, and 150) to provide an extended workstation for integration of additional modules and lab ware.

The entire Xiril robotic system can be configured to meet customised requirements, from the worktable size and pump volumes through to additional functional modules.

Maximum Liquid Handling Flexibility

Xiril has a 1-tip, 2-tip or 4-tip liquid handling arm with selectable and exchangeable pump volumes. Each pump is equipped with a tip adaptor that fits disposable tips with or without filters. For added flexibility and increased sample throughput, the Xiril 100 and 150 can be configured with an additional liquid handling arm for specific life science applications.

An Automated Electronic Hand Pipette

Xiril instruments incorporate the established technology of electronic hand pipettes into a flexible robotic workstation to create an accurate and precise liquid handling system. We use air displacement to aspirate and dispense liquids to eliminate dilution and reduce contamination risk. Each tip is equipped with an individual pressure-based sensor system for liquid level detection, clot detection and clogged tip detection so we can provide you with the reliability you expect from an automated system.

Robotic Plate Handling

Microplates can be transported between pipetting positions and modules with the PlateGripX, a plate handling tool that generates robotic multifunctionality.

Tailored Functionality

The workspace can be adapted for simple through to highly complex applications with the integration of microplate format functional modules and lab ware. A CCD barcode scanner (TubeScanX) enables positive sample identification whilst a microplate shaker (ShakeX) can perform liquid mixing after dispense actions.

The Lirix Application Software

Xiril instruments are controlled by Lirix; a modular software package with a multi-level architecture that fully supports even the most challenging pipetting applications. Its easy-to-use graphical interface reduces set up time as well as training efforts, and it comes with a sophisticated user management.

|

| Specifications |

|

Instrument Configuration

Dimensions

x: 76 cm (30")

y: 52 cm (20")

z: 66 cm (26")

w: 35 kg (70 lbs.av.)

Deck Capacity

12 microplate positions

Arms

1 arm

Channels per Arm

1 or 2 channels

Instrument Power

170 VA

Platform Specs :

Software

Software, Operating System

Lirix Software Package, Windows 2000, Service Pack 2 or higher

Computer and Communication

Computer

Embedded in pipetting deck

Technical data: Pentium III, 256 MB RAM, 20 GB HD

Communication: 2 serial ports RS-232, 2 USB ports, 1 parallel port, LAN (RJ-45)

Communication

High speed CAN bus; max speed of 1MBit/sec; 2-6 CAN ports in support stands

Robotic Performance

Position Accuracy

in X/Y/Z: +/- 0.2 mm

Plate Handler Plate-GripX”

Lifts objects up to 400 g (0.9 lbs.av.)

Pipetting Performance

Tip Types

Disposable tips with and without filters; channels with independent Y and Z movement

Pump Sizes

Medium pumps : 250 µl Large pumps : 1’000 µl

Volume Ranges

Medium tips : 2-250 µl Large tips : 10-1’000 µl

Liquid Detection with Pressure Sensor

* Single or multiple detection, independent for each channel

* Liquid level detection and clot detection

Pipetting Techniques

Container Format

Lirix supports all liquid container formats up to 384-well plates

Pipetting Skills

Single pipetting, multi pipetting, parallel pipetting, aliquoting, archiving

Serial dilutions, pre-dilutions, multiple common pre-dilutions

Liquid mixing in source and destination container

Optional Devices

Plate Handler “Plate-GripX”

Gripper fingers are manipulated with two tip adapters

Barcode Scanner “Tube-ScanX”

Most common barcode types (e.g. Code 39, Interleaved 2 of 5, Codabar, Code 128, etc.)

Plate Shaker “Plate-ShakeX”

Linear and orbital shaking mode with speed range 100-2’000 rpm and an amplitude of 2 mm

Heating / Cooling Devices

Temperature control devices for microplates, tubes and customized racks and containers

SPE Vacuum Station

Vacuum-based solid phase extraction device for NA and protein isolation

Magnetic Bead Station

Magnetic bead separation for NA and protein isolation

Power Supply Input

Voltage, Frequency, Power

Embedded in pipetting deck; 100-230 VAC; 50–60 Hz

Regulatory Standards

In compliance with CE standards (bears the CE mark)

Environmental Conditions

Temperature

Operating:15-35°C (59-95°F);

Storage: 10-50°C (50-122°F)

Relative Humidity

Operating and storage: 30-80 % rH (non-condensing) at 30°C (86°F)

|

|